I decided to learn more about designing circuit boards with Eagle after reading an article about cheap chinese PCB manufacturer. Although there were some problems with their test boards the service is so cheap (about $1 for 5×5 cm board) that I wanted to try it.

For practice project I chose the pethouse heater described in previous blog. After spending some evenings with eagle I managed to produce required files to place an order at IteadStudio. The files were sent by e-mail and they confirmed that order was received. After that I didn’t got any messages from them, although I thought they were supposed to send some kind of shipping confirmation.

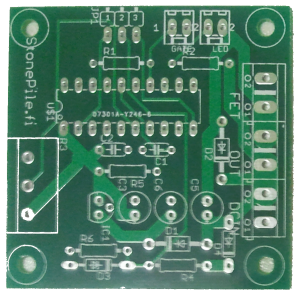

Anyway, after a few weeks I had a package at local post office. The board looks ok, but I noticed that I made some beginners mistakes (I should have read this before sending board to manufacturing) with my design when I started soldering parts to it. The bottom of board is filled with copper (a ground plane) but the isolation between solder pads is very small. As I forgot to specify it’s width the minimum from design rules was used (6 mils). Another mistake with ground plane was that I used thermals on high-current solder pads also. I had to remove solder mask around those pads and fill the gap with solder in order to be able to pass required current (about 6 A).

Anyway, after a few weeks I had a package at local post office. The board looks ok, but I noticed that I made some beginners mistakes (I should have read this before sending board to manufacturing) with my design when I started soldering parts to it. The bottom of board is filled with copper (a ground plane) but the isolation between solder pads is very small. As I forgot to specify it’s width the minimum from design rules was used (6 mils). Another mistake with ground plane was that I used thermals on high-current solder pads also. I had to remove solder mask around those pads and fill the gap with solder in order to be able to pass required current (about 6 A).

No other problems (none with manufacturing), so I replaced the prototype board on heater with this one and the system still works 🙂

The minimum order was 10 boards, costing a little more than $10 with shipping. Now I have extra 9 boards for future PWM controller projects!